CO Catalyst Services

Groome offers a variety of CO Catalyst services nationwide. Our quality-driven methods are value engineered and proven effective.

Our CO Catalyst services are completed turnkey and minimal plant support is required. While our focus remains on the entire life cycle of a complete catalyst system, our offerings extend beyond just the catalysts themselves.

CO Catalyst Testing

Groome partners with industry-leading independent catalyst testing labs to provide the most comprehensive results. These tests replicate your plant’s current operating conditions to take the guesswork out of predicting catalyst end of life. The tests also include chemical and physical analysis to help determine sources of catalyst performance losses.

CO Catalyst Cleaning

There are two basic methods of cleaning CO catalyst’s: In-Situ Mechanical Cleaning and In-Situ Water Washing. The benefits of these cleaning methods include maximizing exhaust flow, minimizing pressure drop and maximizing the catalyst’s useful life.

Learn More

In-Situ Mechanical Cleaning

Catalyst blocks are air-blast cleaned using regulated pressures and proprietary nozzles to prevent damage to the catalyst. Upstream and downstream faces are then vacuum cleaned to remove bulk foreign object debris and assist in drawing out contaminants. If needed, catalyst blocks are then repacked with new OEM gaskets.

In-Situ Water Wash

After a mechanical cleaning, demineralized water is introduced to flush out more stubborn obstructions and ‘scrub’ the internal surfaces. All process water is vacuum-recovered and all surfaces are dried. If needed, catalyst blocks are then repacked with new OEM gaskets.

CO Catalyst Repacking

During normal operation, it is possible for insulation or gaskets to shift or move out of place, creating extra bypass and effecting system performance. A basic repacking of these materials might be all that is needed to fix minor performance issues.

CO Catalyst Rejuvenation

If a CO catalyst has been tested and results show a steady decrease in performance with the end of life in sight, your next step may be a catalyst rejuvenation service. The purpose of this service is to improve overall catalyst activation, in turn extending the useful life of the catalyst.

Learn More

A rejuvenation study (AKA a wash study) is required to verify the validity of a rejuvenation and to identify the specific type of wash necessary for maximum results.

For those that qualify, the catalyst system is first mechanically cleaned with air to remove the bulk contaminants. Next, all catalyst blocks are removed and placed in a specially formulated water or acid wash. Depending on the results from the wash study, this wash may also be heated for a more effective rejuvenation. Finally, all catalyst blocks are dried and reinstalled with OEM specified gaskets and insulation.

CO Catalyst System Modification

There are many reasons why a CO catalyst system may need modifications. Whether your facility needs to fix damaged framing, is upgrading or adding catalyst volume, or is having sealing or flow issues, Groome has the knowledge and experience you need to get your system operating the way it was meant to.

Groome works on any

MAKE, MODEL, or AGE

Catalyst

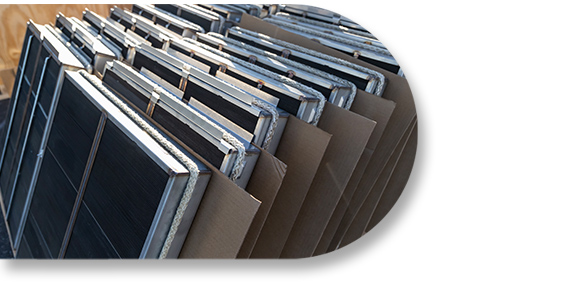

CO Catalyst Supply & Replacement

Groome’s in-house engineering team works closely with several HRSG and catalyst OEM’s when sourcing your new catalysts. During the replacement, Groome is responsible for all scaffolding, crane support, rigging, and welding services needed for a smooth installation.

CO Catalyst Reclamation

Old CO catalysts can be reclaimed for their precious metal content and we offer the industry’s leading value to those chemical contents. This value can help in paying for your new CO catalysts.

Safety Is Paramount at Groome

We follow IME/OSHA-based safety training programs, along with an OSHA 10 training standard for all employees.

An accident-free environment translates to lower insurance costs, better employee commitment, higher productivity, and an improved bottom line for our customers.