Ammonia Injection Grid (AIG) Services

The Ammonia Injection Grid is one of the keys to maintaining an efficient SCR catalyst system.

The Ammonia Injection Grid is often overlooked when discussing NOx conversion efficiencies. Groome knows the importance of these efficiencies and the effects they can have on a plants overall performance.

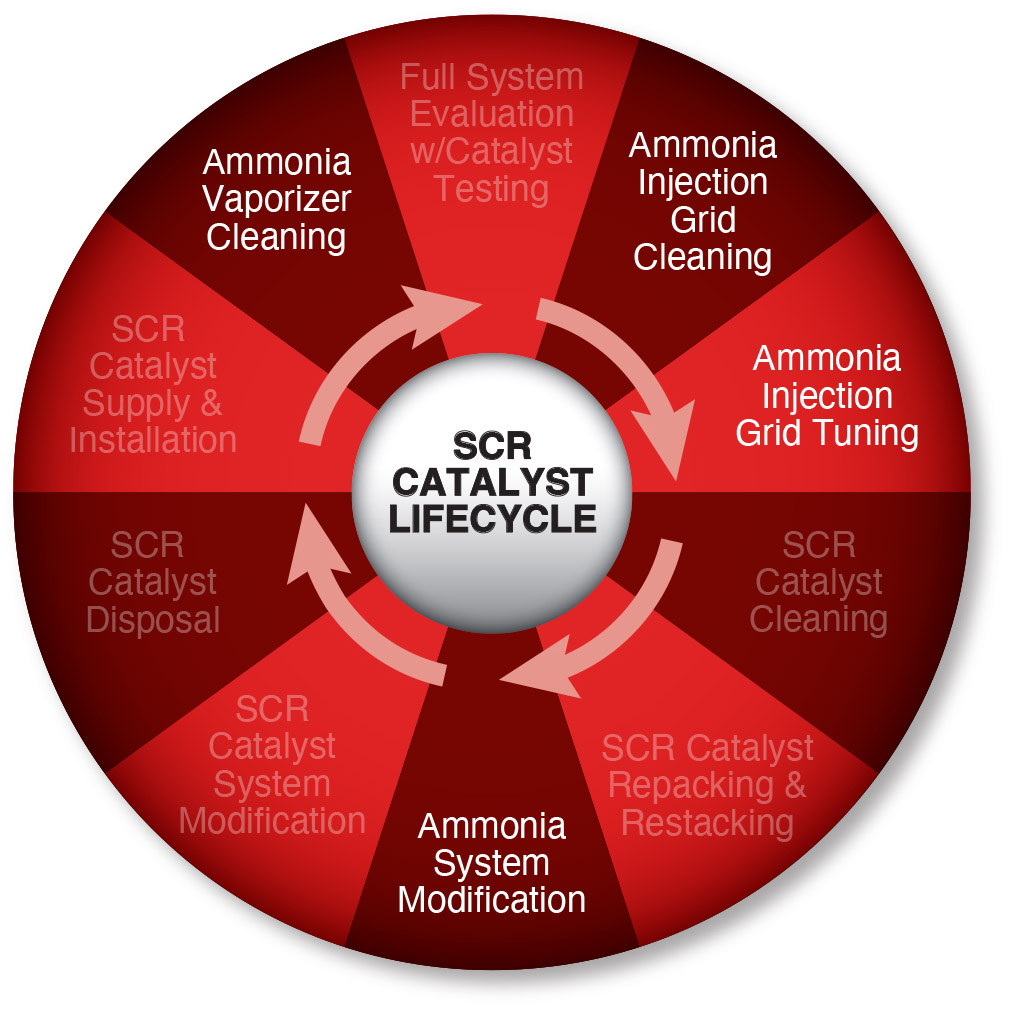

Ammonia Injection Grid Cleaning

We offer a variety of cleaning options for your Ammonia Injection Grid. Nozzle cleaning, heavy duty vacuum / agitation cleaning, and water jetting are all considered when recommending a work scope depending on your specific situation. Benefits of an AIG cleaning include improved ammonia distribution and lower ammonia consumption.

Ammonia Injection Grid Tuning

AIG tuning allows for the most accurate ammonia dispersion across the face of a catalyst. Our tuning services include all lift equipment, test port installation, valve adjustments and stack testing. Benefits of an AIG tuning include decreased ammonia consumption, decreased ammonia slip, and an increase in NOx conversion.

Learn More

Installation of a Permanent Sampling Grid

An effective way to tune the AIG is through the use of a permanent sampling grid. Permanent sampling grids are custom designed to provide the optimal grid for the AIG tuning process no matter the configuration of the unit. Benefits of a permanent sampling grid include:

• No lift required when tuning

• Minimal time needed for AIG tuning

• Reduce ammonia consumption

• Identify areas of exhaust bypass

AIG System Modifications

Upgrading ammonia delivery systems to meet the ever changing demands of plant performance is crucial. Groome can help, with projects ranging from lance replacements and nozzle optimization to complete ammonia skid replacement.

Ammonia Vaporizer Cleaning

Vaporizer units are water jetted to remove buildup in the drip rings. A specialty chemical is used to remove buildup inside the vessel, then the vessel is mechanically agitated to assist in further cleaning. This process is repeated until the unit is thoroughly cleaned. Benefits include an increase in ammonia efficiency and flow and improved NOx conversion.

What is Ammonia Slip?

When too much ammonia is injected into the HRSG, the excess can slip through the SCR catalyst resulting in an incomplete reaction. Any leftover ammonia is wasted in the exhaust.

Commonly know as “ammonia slip”, this unwanted overdose can cause increased emissions and the formation of salts, fouling and corrosion on downstream surfaces.

Safety Is Paramount at Groome

We follow IME/OSHA-based safety training programs, along with an OSHA 10 training standard for all employees.

An accident-free environment translates to lower insurance costs, better employee commitment, higher productivity, and an improved bottom line for our customers.