This three part series on the patented kinetic energy cleaning process was penned by Jeff Bause, President & CEO of Groome Industrial Service Group.

Clean is good. Very good.

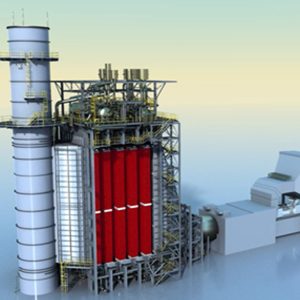

And in the world of power generation, a clean HRSG (heat recovery steam generator) means no foulants in the fin tubes, economizer sections, and other areas.

There are many reasons why a clean HRSG is desirable. Removing the fouling from the fin tube banks decreases backpressure, increases megawatt output, increases the heat absorption of the tubes, lowers flue gas temperature, and improves the BTU efficiency of a HRSG.

The clean HRSG is then beneficial for the environment as it translates to cleaner air and a more healthful environment. As well, when a facility runs cleanly, it runs efficiently and saves on natural resources and reduces the amount of energy needed to keep operations going – which is not only beneficial for the environment but also for a company’s bottom line.

The clean HRSG is then beneficial for the environment as it translates to cleaner air and a more healthful environment. As well, when a facility runs cleanly, it runs efficiently and saves on natural resources and reduces the amount of energy needed to keep operations going – which is not only beneficial for the environment but also for a company’s bottom line.

While there is agreement that clean is good, the question becomes what is the best method to clean. There are many traditional methods of cleaning, such as those that utilize ice, water, and foam. While there is a place for these methods, there is an innovative technology that is better for the environment on many levels. This method incorporates the use of kinetic energy.

The kinetic energy option

Kinetic energy, in its simplest form, is the energy that an object has because of its motion. When force is applied to an object to accelerate the object, energy has been transferred to the object. The object will then move. This energy transferred to the object is known as kinetic energy.

Kinetic energy is an innovative way to clean facilities such as HRSGs, as it takes the learnings of kinetic science and applies one of the deepest cleans available. It is through the use of this type of energy and its associated technology that arguably the most thorough maintenance can be completed.

How kinetic cleaning works

At its simplest level, the kinetic energy cleaning process very effectively dislodges fouling deposits on fin tubes. The procedure includes the setup of a detonating cord curtain which is engineered for a specific application, based on the size of the area to be cleaned and the amount of fouling of the individual HRSG.

The detonation itself is engineered to be the most effective in delivering kinetic energy while at the same time ensuring the structural integrity of the tubes is not compromised. The detonation occurs along the entire length at a velocity of approximately 22,000 feet per second to safely and effectively remove hard deposits. There is no tube spreading required, and no tools come into direct contact with the tubes.

After detonation of the deck cord curtain, there will remain on the tube fins some fouling material that has been loosened but not yet removed. It is crucial that this foulant is removed to get the most thorough cleaning possible. This takes place via a patented oscillating air tool that delivers high-volume, high-pressure air through a programmable operating system. This removes any of the remaining debris that was initially loosened by the kinetic energy system but has remained on fins after the initial wave of cleaning. Vacuuming then extracts all liberated debris from the unit to complete the cleaning process.

In addition to the deepest clean available, there are other benefits obtained by tapping into the power of this kinetic energy process. There is no manual tube movement, and there is no additional moisture. During the prep and hanging of the det cord curtain, coordinated maintenance efforts can be continued within the HRSG where the kinetic energy cleaning takes place. And no scaffolding is required, meaning all the associated hassles and related dangers of utilizing that type of equipment are removed.

Part 2 and 3 of the series will look at Case Examples.