Groome’s expert refinery maintenance services and emission control technologies help facilities run more efficiently and cost effectively.

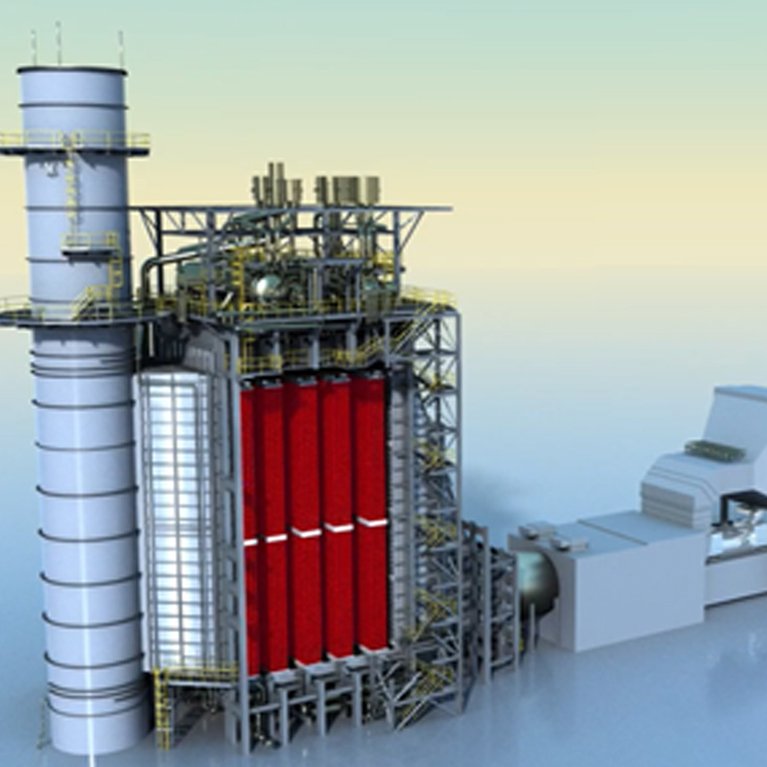

CATALYST SERVICES – SCR

Groome offers a variety of SCR catalyst services with quality-driven methods that are value-engineered and proven highly effective within refineries. Our work focus remains on the entire life cycle of a complete catalyst system – our offerings extend beyond catalyst itself. As well, Groome SCR cleaning can take place while a facility continues operations to deliver a strong ROI.

KINETICLEAN

Groome’s innovative and patented KinetiClean technology uses a proven Kinetic Shockwave cleaning method focused on cleaning and removal of unwanted foulant. A patented air system utilized after the blast features automated high-pressure, high-volume air distribution. Groome follows IME/OSHA-based safety training programs, along with an OSHA 30 training standard for all employees.

EXPLOSIVE CLEANING SERVICES

Our explosive cleaning system has a four-decade track record of safely and successfully cleaning facilities across industries that include refineries. Foulant and debris are removed through the controlled use of explosives by our highly-trained team of professionals. Our process includes a system that ensures the team and all refinery assets remain safe and undamaged.

WATER CLEANING SERVICES

Environmentally friendly and highly effective, Groome’s water cleaning systems deliver the best results in the industry. High-pressure water removes foulant materials and contaminants within a refinery quickly and safely, without the use of abrasives or chemicals.

INDUSTRIAL CLEANING SERVICES

Groome Industrial provides outstanding services for additional cleaning applications as well as supplemental labor and support services for refineries. From dry ice cleaning and foam blasting to additional manpower, think of Groome to get projects done quickly, efficiently, and safely.

INDUSTRIAL COATING SERVICES

A variety of coating services are required in refineries, and Groome has the expertise to handle any size project ranging from maintenance touch-ups and corrosion arrests to large-scale projects. Whatever the size or complexity of the project, we have the expertise to assist from the planning phase through to successful completion.