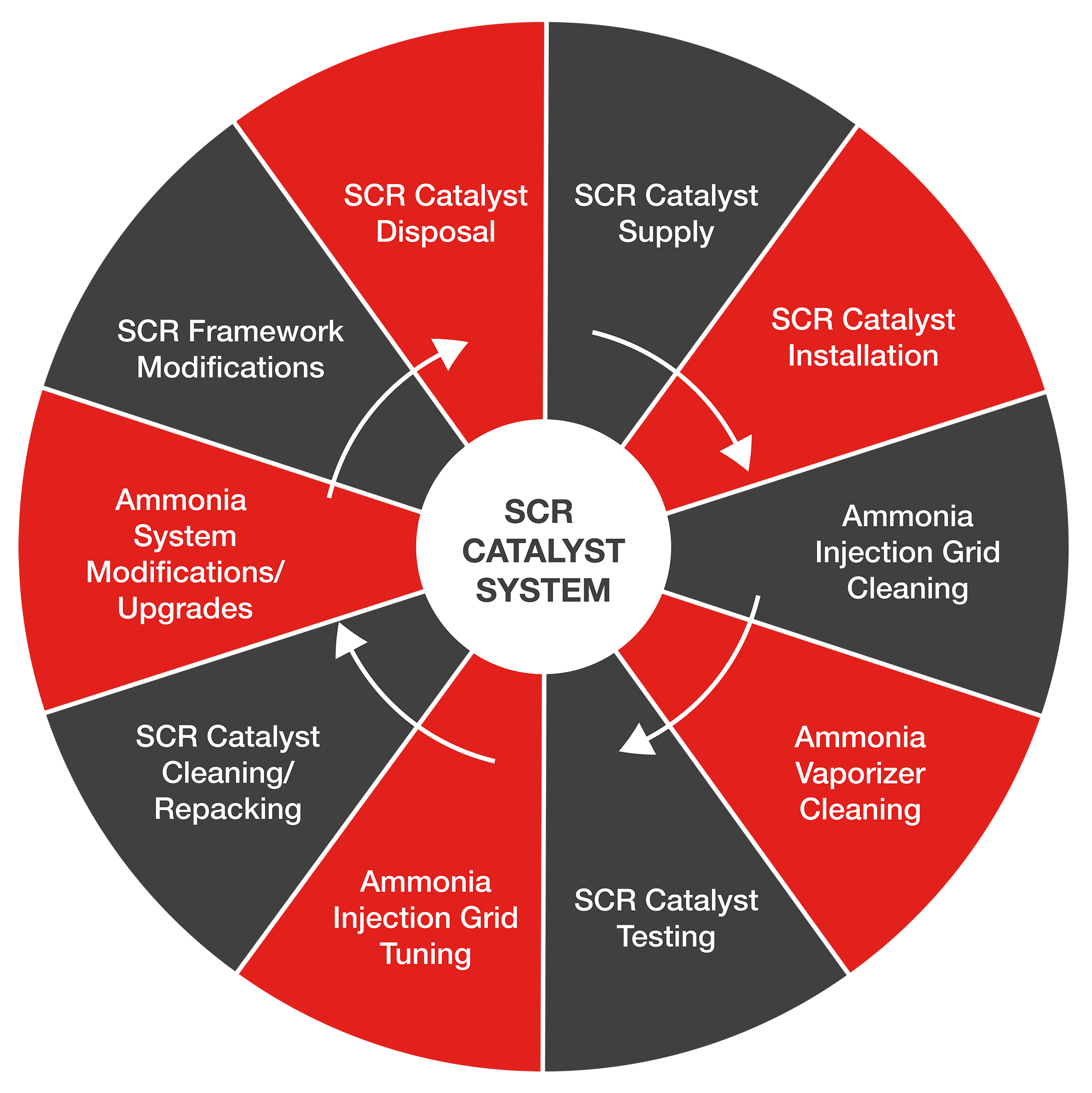

SCR Catalyst Systems

IN-SITU MECHANICAL CLEANING & REPACKING

When units age, consume too much ammonia, put unnecessary pressure on the turbine, or are out of compliance with NOx, NH3, and/or CO emissions, a complete catalyst system evaluation and system maintenance is often required.

Catalyst units are air-blast cleaned using regulated pressures and OEM approved proprietary nozzles to prevent damage to the catalyst. Upstream and downstream faces are simultaneously vacuumed and air blasted to remove bulk foreign object debris and assist in drawing out contaminants. Shifted catalyst blocks are repositioned to their original orientation and repacked with new OEM gaskets.

THE BENEFITS

- Maximize air flow through catalyst

- Maximize catalyst life

- Minimize pressure drop

- Expose active conversion sites

- Improve turbine efficiency

- Reduce ammonia slip

- 10″ decrease in back pressure/ d.p.

- 45% reduction in ammonia usage

TURNKEY SCR CATALYST REPLACEMENT

Groome has partnered with the industry’s leading SCR catalyst manufacturers to offer our customers the most turnkey solution available today.

SCR Catalyst Supply

This SCR catalyst creates less back pressure due to its larger pitch design. The flue gas path of the SCR also permits more catalyst volume per cubic meter. These characteristics will improve turbine performance while still allowing your facility to maintain its current emission permit levels. Groome can supply a full-scale replacement utilizing the industry’s leading manufacturers of SCR catalysts.

SCR Catalyst Installation

Our crews are catalyst specialists who know how to handle the SCR modules properly. Groome has the engineering services to help create solutions to any problems in gasketing, pull mechanisms, or any other issue, quickly and effectively. We provide a turnkey service including all scaffolding, crane support, rigging and welding.

SCR Catalyst Disposal

Our industry partnerships allow us to take the headache and guesswork out of proper disposal of spent catalysts. SCR catalysts are transported off site, all steel is recycled, and the catalyst is mechanically deconstructed. All proper paperwork is then returned to the plant for record keeping.

SCR MODULE REALIGNMENT

We provide restacking of the SCR to maintain proper flow and limit any bypass caused by entire modules shifting.

SCR CATALYST SEALING

Our effective SCR sealing solutions limit any bypass that could pass through the SCR section. Utilizing industry-leading insulation pillows and cutting-edge baffle designs ensure an effective seal from design to crew installation.

Before