Your Fall Cleaning List:

SCR Catalyst Cleaning with Groome’s Team of Experts

WHAT IS SCR CATALYST CLEANING & WHY IS IT IMPORTANT?

It’s that time of year to ensure fall cleaning is on the calendar – a perfect time to examine how things are running “under the hood” of your valuable plant and boiler equipment. During any power plant or refinery equipment inspection, it is imperative to pay attention to NOx emission levels and ensure they comply with ever-tightening EPA regulations. If you find that your equipment has become non-compliant with NOx, NH3 and/or CO emission levels, or if your boiler unit is consuming too much ammonia, it’s best to start with a complete evaluation of the unit’s catalyst system. It is likely that your Selective Catalytic Reduction (SCR) catalyst system needs to be cleaned and repacked. In this article, we will explore how Groome Industrial Service Group approaches in-situ catalyst cleaning and what the benefits are for operators.

HOW DO YOU CLEAN A CATAYLST IN-SITU? Catalyst systems can contain potentially harmful contaminants that are difficult to reach or remove using traditional cleaning methods. The catalyst system remains sedentary while units are air-blast cleaned using regulated pressures and OEM-approved proprietary nozzles. Upstream and downstream faces are simultaneously vacuumed and air-blasted to remove foreign object debris and draw out contaminants. The four primary benefits of an in-situ SCR catalyst cleaning include improved NOx conversion, decreased pressure drop, decreased ammonia slip and increased plant efficiency.

WHAT ARE THE OTHER BENEFITS?

Improved/Increased

- Catalyst Life

- Catalyst Surface Area

- Plant Efficiency

- Power Quality

- Power Reliability

Reduced/Decreased

- Catalyst Poisoning

- Fan Power Consumption

- Operating Costs

- Risk, Load De-Rating, Boiler Shutdown

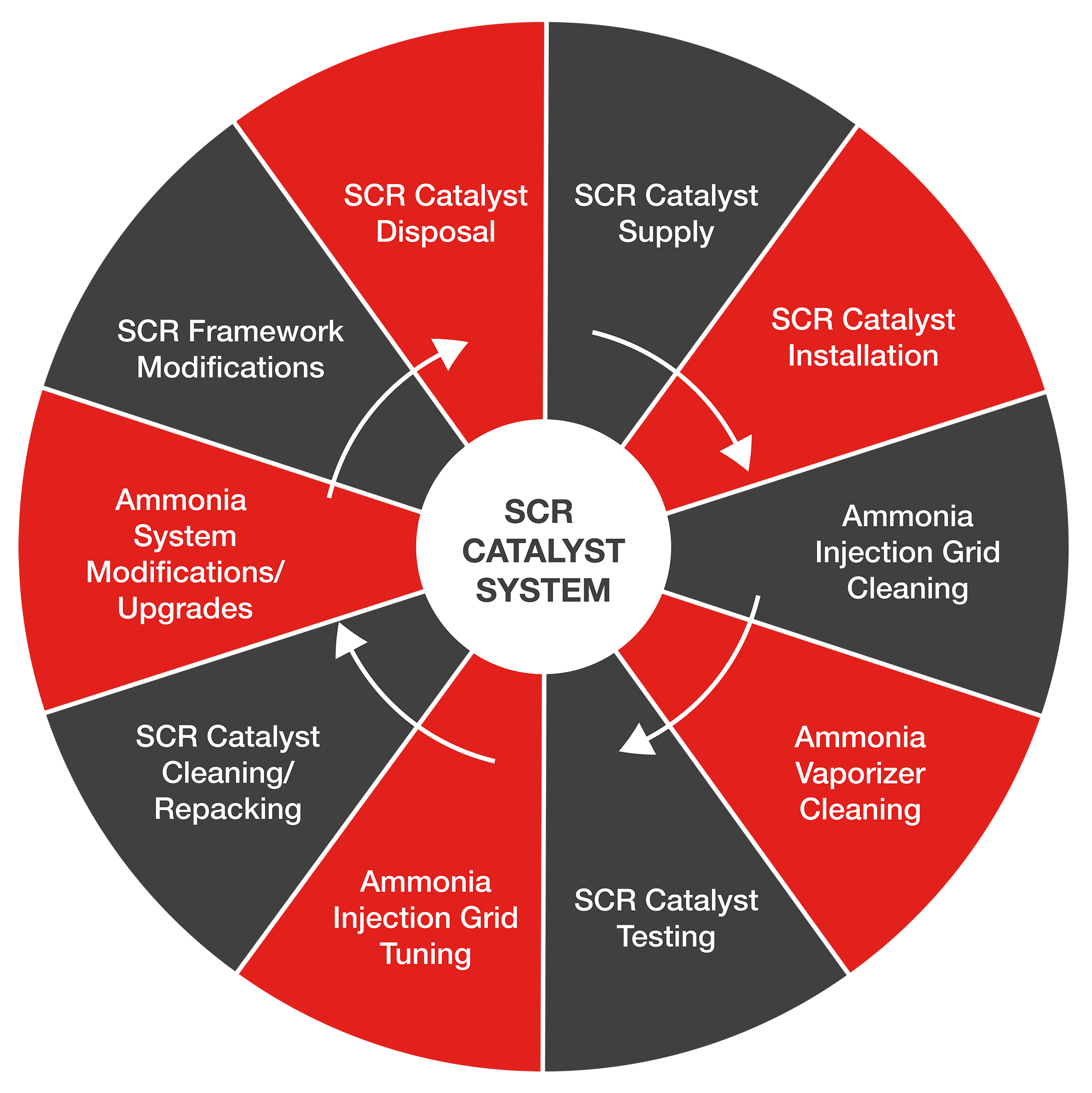

There is no escape from having to perform system maintenance on your valuable operating equipment and having the right team in place is of significant importance. In operation for over 50 years, Groome Industrial Service Group offers the most widely-supported, comprehensive, turnkey solution available for SCR catalysts today. However, our service offerings extend beyond just the catalyst. We concentrate on the entire life cycle of a complete catalyst system. In addition to in-situ SCR catalyst cleaning, Groome also provides SCR catalyst supply, installation and disposal.

SIMPLIFIED SOLUTIONS

Groome is a proven industry-leader and the maintenance provider of choice. Focused on the future, our philosophy is simple: provide quality, innovative maintenance services nationwide at a reasonable price. Industries that benefit from Groome’s services include natural gas-fired power generation, refinery & petrochem, manufacturing, pharmaceuticals, and aerospace.

Ready to schedule the fall cleaning for your SCR catalyst? Tell us when your next outage is, and we will take it from there.

Contact Steve Houghton, VP of Sales shoughton@groomeindustrial.com 551-502-6357